Contract Welding for OEMs & Contractors

GWC provides contract welding when OEM & Contractor welding demand exceeds internal welding capacity.

$100M+

Welded Products

15,000+

25,000+

Welds Inspected

Welding Records

40,000+

Managed Welding Hours

Modular • HVACR • Energy • Infrastructure • Industrial • Commercial

How We Help Our Customers

-

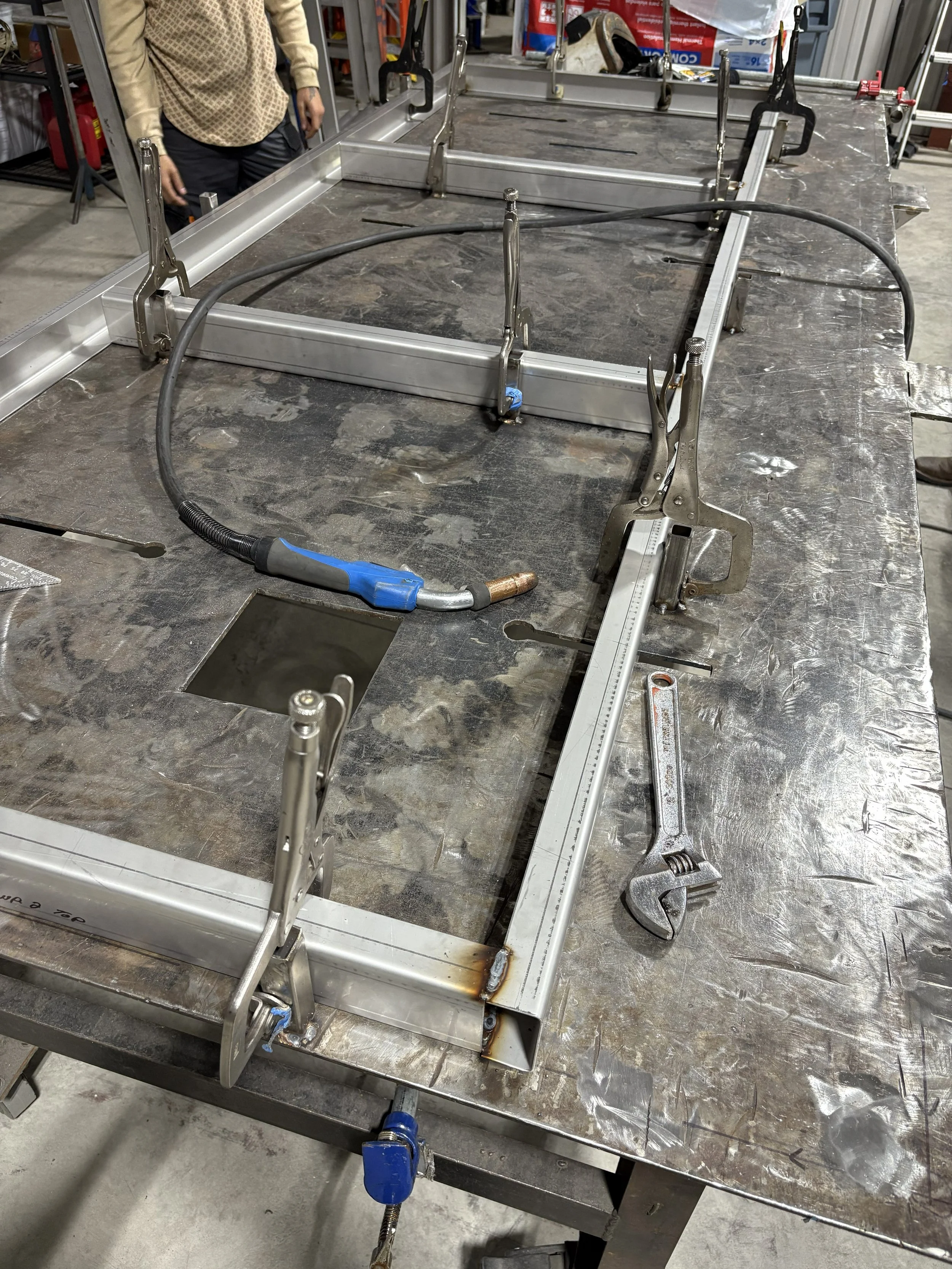

Contract Welding

Our shop and traveling contract welders have supported over $100M in manufacturing output.

When welding becomes the bottleneck, 10+ OEM programs deploy GWC’s contract welders.

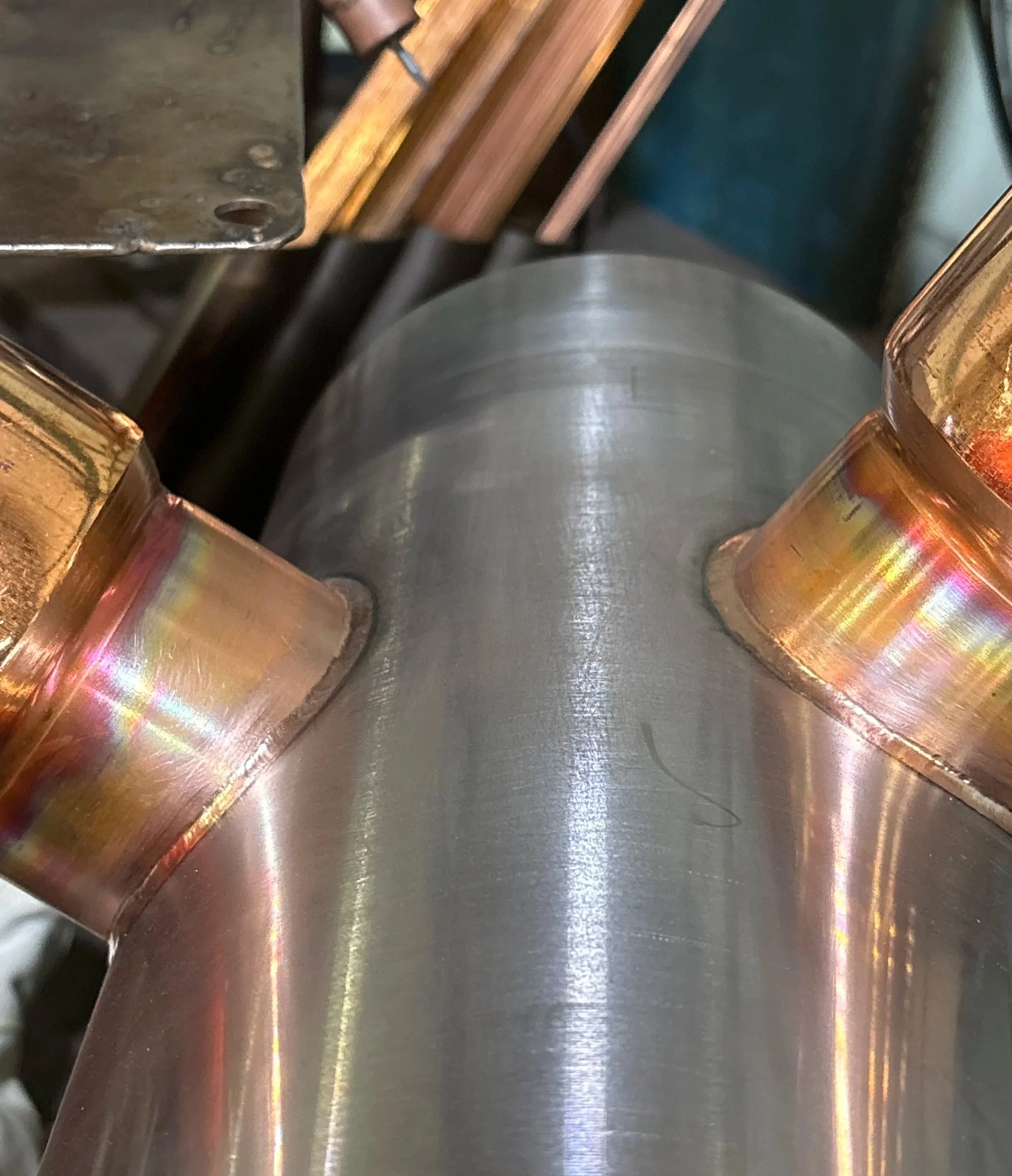

GTAW, SMAW, GMAW, FCAW, Laser, and more

Sanitary & Food Grade environments

ASME & ISO-regulated work

We learn your drawings & requirements then we work under your direction to ensure alignment with your standards.

Why? So you can feel relief from welding constraints.

-

Welding Inspection Management

We’ve inspected 15,000+ welds across the U.S.

Overseen more than 40,000 welding man-hours inside regulated environments.

50+ certified welders covered per day.

20+ managed CWI’s per site.

100+ inspected welds per day.

100s of miles of welding documentation.

25,000+ weld records with traceability.

Codes we work under: PHMSA, ASME B31.1, B31.3, Section IX, API 1104, AWS D1.1, ISO 9001, and more.

What Clients Say

Examples Of Our Work

Common Questions

What types of welding do you offer?

We provide contract welding for manufacturers, OEMs, and industrial customers, including production welding, repair work, and welded assemblies.

Do you provide contract welders at a customer’s facility?

Yes. Greenville Weld Company can provide contract welders to work at your facility under your direction, depending on scope, schedule, and location.

Can you handle production welding at your own shop?

Yes. We can complete welding work at our facility for customers who need overflow support, outsourced welding capacity, or welded product manufacturing.

What industries do you support?

We support OEMs, manufacturers, industrial contractors, and other businesses that need reliable welding support for production parts, assemblies, and industrial components.

Can I send drawings or photos for review?

Yes. If you have drawings, photos, or part details, send them over and we can review the job and discuss next steps.

Our

Team

-

Michael Bates (AWS CWI & OWNER)

With a decade in the field and almost another in the office, Michael leads Greenville Weld Company’s operations and quality oversight with not-so-common southern grace. As a Certified Welding Inspector and hands-on fabricator, he brings deep code compliance and real-world results to every project.

For larger jobs, GWC taps into a network of trusted inspectors & regional welders and machinists — so you get the best crew for your project, every time.

You get the owner’s attention on every job—period.